A university design graduate is demonstrating the enormous potential of 3D printing by using the technique to create inflatable rubber-like flowers. The vast majority of products created by 3D printers are rigid in form but designers like Richard Clarkson, from Victoria University in the New Zealand capital of Wellington, are using new materials to produce morphing 3D shapes.

His ‘seamless blossom project’ includes flowers that open up when air is pumped into them to provide a flash of colour. He believes they are the first ever 3D-printed inflatable products.

Mr Clarkson, who has a design studio in New York, said the flowers have a curved hollow chamber made of rubber. Inflation produces a gap of air that forces the outer layers open and it ‘blooms, like a flower”.

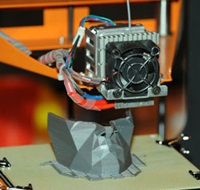

He created them with Objet’s multi-material printer that allows flexible and rigid materials to be printed at the same time. No electronics, sensors or computers are needed, just air pressure, he said.

It is thought that his work will be the first of many 3D-printed products using a wide range of materials.